EV Fleet Maintenance vs ICE: What Your Workshop Software Must Handle?

- Vijay Gummadi

- Oct 31, 2025

- 4 min read

Executive Summary

The automotive industry is undergoing a significant transformation as electric vehicle adoption accelerates. Fleet operators managing both electric and internal combustion engine vehicles require specialized software solutions that address the unique maintenance requirements of each platform while providing unified operational visibility.

The EV Maintenance Paradigm Shift

As electric vehicle (EV) adoption surges, fleet operators must rethink traditional repair workflows. Unlike ICE repairs, EV fleet maintenance demands digital traceability, technician safety protocols, and smart inventory mapping. Autorox simplifies this EV transition with purpose-built, cloud-based tools that accommodate the specific requirements of electric vehicle servicing.

From Fault Code to Repair Ticket: Automating EV Diagnostics

How do EV fault codes translate into service jobs?Modern EVs generate real-time alerts via their onboard telematics systems. These diagnostic codes must quickly become actionable job cards to minimize vehicle downtime and maintain fleet efficiency.

Critical Software Requirements:

Automated fault-code-triggered job card creation

Categorical job tagging: Scheduled Maintenance, Warning, Breakdown, Fault Code, etc.

Service type tagging: HV Maintenance, LV Maintenance, General Maintenance, etc.

Automated SLA timer initiation upon job card creation

Autorox Solution: Intelligent fault-tagged repair tickets with incident tagging, fault code capture.

Safety Checklists: Protecting Technicians from High-Voltage Risks

Why is safety critical in EV repair?

Electric vehicles operate with high-voltage systems ranging from 400V to 800V, requiring stringent safety protocols during maintenance operations. Safe repairs demand comprehensive pre- and post-inspection procedures to prevent accidents and ensure technician safety.

Essential Safety Protocol Components:

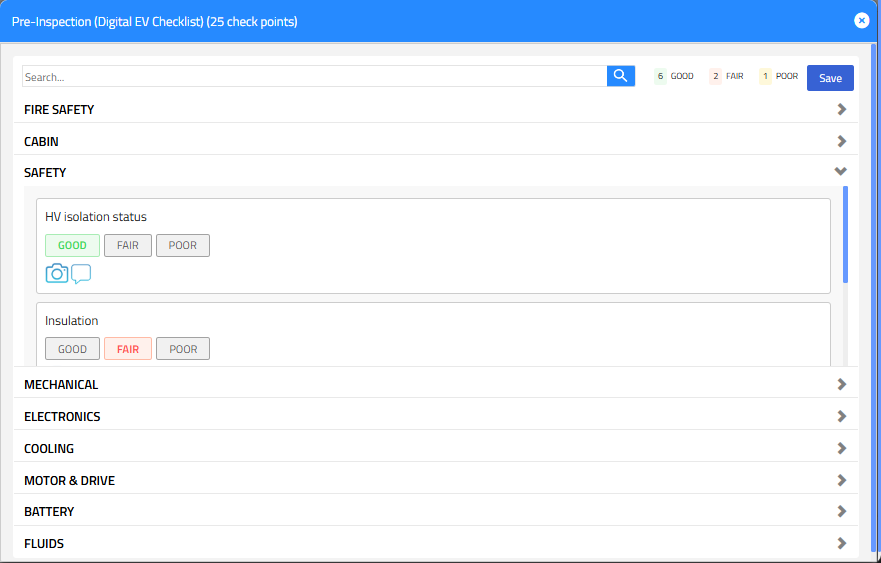

Pre-inspection: PPE verification, HV system isolation, BMS diagnostic scanning

Post-repair: Regenerative braking system verification, insulation resistance testing

Geo-tagged technician sign-offs for compliance tracking

Autorox Solution: Configurable high-voltage safety checklist templates with digital sign-off capabilities and audit trail maintenance.

Role-Based Workflows: Assigning the Right Technician

What roles are essential in EV service operations?

EV repairs require specifically certified technicians due to the specialized nature of electric vehicle systems. Workshop software should automatically route jobs based on technician qualifications, certifications, and role assignments.

Standard EV Service Roles:

HV Certified Technician (battery systems, high-voltage lines)

HVAC Specialist (thermal management systems, battery cooling)

Service Engineer (advanced diagnostics, system analysis)

Supervisor (job audit, quality control, work closure)

Autorox Solution: Role-based job routing with certification-level filtering and qualification matching.

EV Service Types You Can Standardize

Comprehensive battery diagnostics & preventive maintenance

Fault-code-based corrective repairs

Emergency breakdown response (insulation faults, power loss)

Software updates and system recalibration

Autorox Solution: Service type tagging in job cards, customizable per EV model and manufacturer specifications.

Serialized Inventory Tracking for EV Parts

Why traceability matters for EV components?

Electric vehicle parts require enhanced traceability due to higher costs, warranty considerations, and regulatory requirements. Critical components include:

Battery modules and packs

High-voltage cables & connectors

Power inverters and isolation monitoring devices

Essential Inventory Management Features:

Serial number-based individual part tracking

Stock origin and status tagging (in stock, depot, ordered)

Automated warranty registration and tracking

Autorox Solution: Comprehensive serialized inventory management with barcode scanning integration and automated warranty mapping (coming soon).

Managing ICE + EV in One Unified Platform

Can you run ICE and EV workflows together effectively?

Yes - Autorox supports hybrid garage operations with unified dashboards and tailored checklist systems that accommodate both vehicle types while maintaining specialized workflows for each.

Key Integration Features:

Separate ICE vs EV checklist templates within unified system

Shared technician pool with EV specialization tracking

Unified inventory management with category-based tagging

Consolidated reporting across all vehicle types

Autorox Solution: All-in-one operational dashboard for ICE and EV workflows with intelligent technician allocation tools.

Comprehensive Capability Summary: Your EV-Ready Fleet Workshop Solution

To successfully operate in the EV era, your fleet repair infrastructure requires:

Digitized standard operating procedures (SOPs)

Telematics-triggered automated job card generation

Role-based technician routing and certification management

Serialized inventory control with warranty tracking

Real-time repair status visibility and reporting

Autorox delivers complete fleet maintenance management - for electric and internal combustion vehicles alike.

Implementation and Demonstration

Future-proof your fleet servicing operations with Autorox. Automate EV repair workflows, enforce technician safety protocols, and streamline inventory management - all within a single, unified platform.

Extended FAQ Section

Q: What makes EV fleet maintenance different from ICE vehicle maintenance?

A: EV maintenance requires high-voltage safety protocols, digital workflow integration, serialized parts tracking, specialized technician certifications, and different diagnostic approaches compared to traditional internal combustion engine vehicles.

Q: How can I automate EV job card creation in my workshop?

A: Autorox uses automated fault-code triggers from vehicle telematics systems to generate actionable job cards with appropriate priority levels and technician assignments.

Q: What safety certifications do technicians need for EV repairs?

A: Technicians require high-voltage system certification (such as OEM-specific EV certifications) and should follow OSHA/NIOSH guidelines for electrical safety in automotive environments.

Q: Can traditional automotive workshops handle EV maintenance with existing equipment?

A: While some maintenance tasks overlap, EV servicing requires specialized insulation testing equipment, high-voltage PPE, battery diagnostic tools, and software systems capable of managing EV-specific workflows.

Q: How does parts inventory management differ for EVs versus ICE vehicles?

A: EV parts management requires serial number tracking for major components, battery cycle life monitoring, warranty status tracking, and different inventory stratification due to higher component costs and different failure patterns.

Q: What telematics integration is required for EV maintenance automation?

A: Effective EV maintenance requires integration with OEM telematics systems, charging infrastructure data, battery management system alerts, and diagnostic trouble code streaming for proactive maintenance scheduling.

Comments